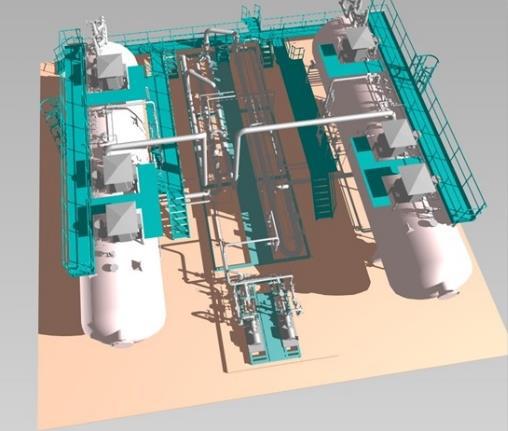

The wet crude oil is fed into the dehydrators/desalters through Howe Baker’s specially designed distribution headers and spreaders which ensure even flow through the unit such that no section of the unit is over or under-loaded and the longest retention time for the crude oil inside the treater with no recirculation inside the treater. This gives the maximum removal of free water and therefore dissolved salts from the crude oil in the fastest possible time, which results in smaller and lower cost vessels.

The headers are positioned in the oil phase below the electrical grid assembly, that is the heart of the electrostatic process.

The wet crude oil flows evenly up through the grid assembly and is subjected to an intense AC electrostatic field created by the high voltage charge imposed on the grid electrodes. The electrostatic field aids the small water droplets to coalesce to form larger droplets and thus be able to separate under gravity from the crude oil.

The water droplets fall to the oil water interface below the inlet distribution headers and the separated water is discharged through a separate pipe under level control. The dehydrated dry oil rises to the top of the vessel where it is collected and discharged through the crude oil outlet piping.

Howe Baker locates the electrical grids to ensure optimum power consumption and maximize the residence time of the crude oil in the electrostatic field, thus allowing the water droplets more time to coalesce and separate from the crude oil.

The arrangement of header positions, electrode layout and interface level position has proven, in the field, the capability of Howe Baker’s systems to handle and resolve fully emulsified crude oils with water cuts in excess of 30%. The high voltage imposed on the grids is achieved by transforming the voltage of a standard AC supply up to a voltage of 14,000 to 22,000 volts using power units and high voltage connection assemblies, electrically certified for use in hazardous areas.

The power unit electrical connections and the unique electrode grid connections ensure a balanced electrical load on all three phases of the electric supply. The power units are specifically designed for dehydrating/desalting applications where the grids may be short-circuited by excessive water slugs in the crude oil. 100% reactance in the power unit ensures that under such upset circumstances the units can stay on line safely, until the upset is cleared, without shutting down the process. Depending on the required quality of the crude oil and the salinity of the feed, more than one stage of desalting may be required.

The Howe Baker desalting systems are capable of reducing the salt content to as low as 1 ppm weight. Multistage desalting systems have two or more desalting vessels in series. The system works by introducing the fresh wash water into the crude stream immediately upstream of the last vessel in the system.

The product crude exits this vessel and the effluent water from this vessel is recycled and is mixed with the crude entering the vessel immediately upstream in the system. This is repeated with the effluent water from each vessel being recycled to the upstream vessel.