Today, many processes have a requirement for a high quality hydrogen feed, in some cases to chemically react with other feedstocks to form new products and in other cases to provide a reducing atmosphere to prevent oxidation. Increasingly the need is driven by environmental concerns, most specifically in refineries worldwide that are aiming to reduce both sulphur and aromatics in their products.

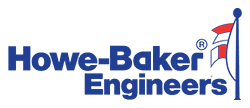

The hydrogen required can either be produced by generating it, using a steam reforming or methanol cracking process, or recovering if from a hydrogen rich process stream by using the Pressure Swing Adsorption (PSA) process. Hydrogen rich process streams, readily available in refinery and petrochemical complexes, are sometimes sent via the fuel main to be burnt. The PSA process provides a low cost method of increasing the availability of high purity hydrogen and providing better utilisation of these “waste” streams.