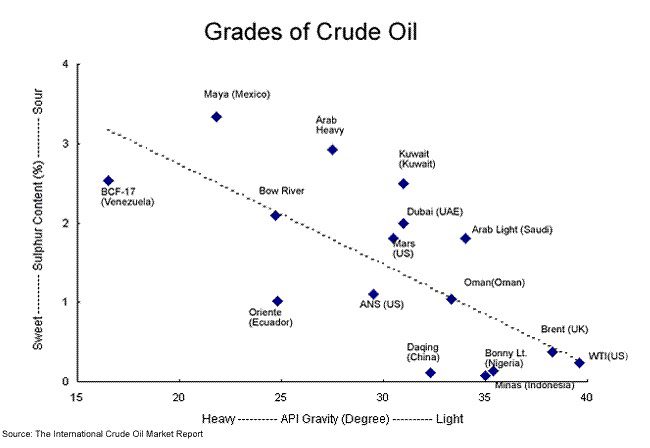

When someone calls asking how much a 10,000 barrel per day mini refinery would cost, it depends on:

- API gravity

- Sulfur content

- Products desired

- Sulfur specifications on finished products

- Ability to switch between different crudes

There are no two mini refineries alike. The ability to switch between light and heavy crudes means that one crude may require a larger naphtha hydrotreater, a larger naphtha reformer, and a larger diesel hydrotreater, whereas the other may not. We typically analyze many crude scenarios for your mini refinery to determine the best configuration and process unit sizes during the feasibility study, which is performed at the beginning of any new project.

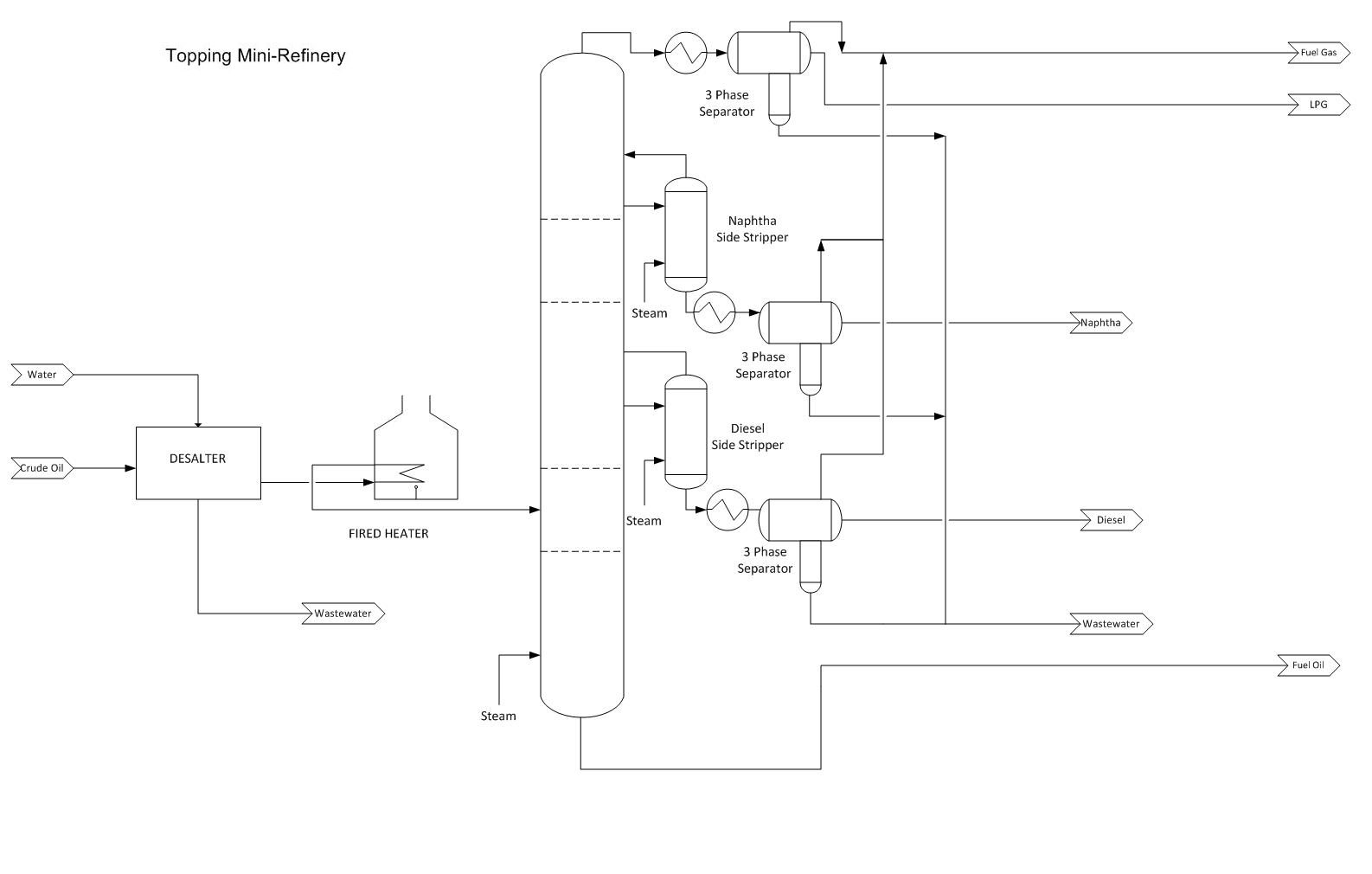

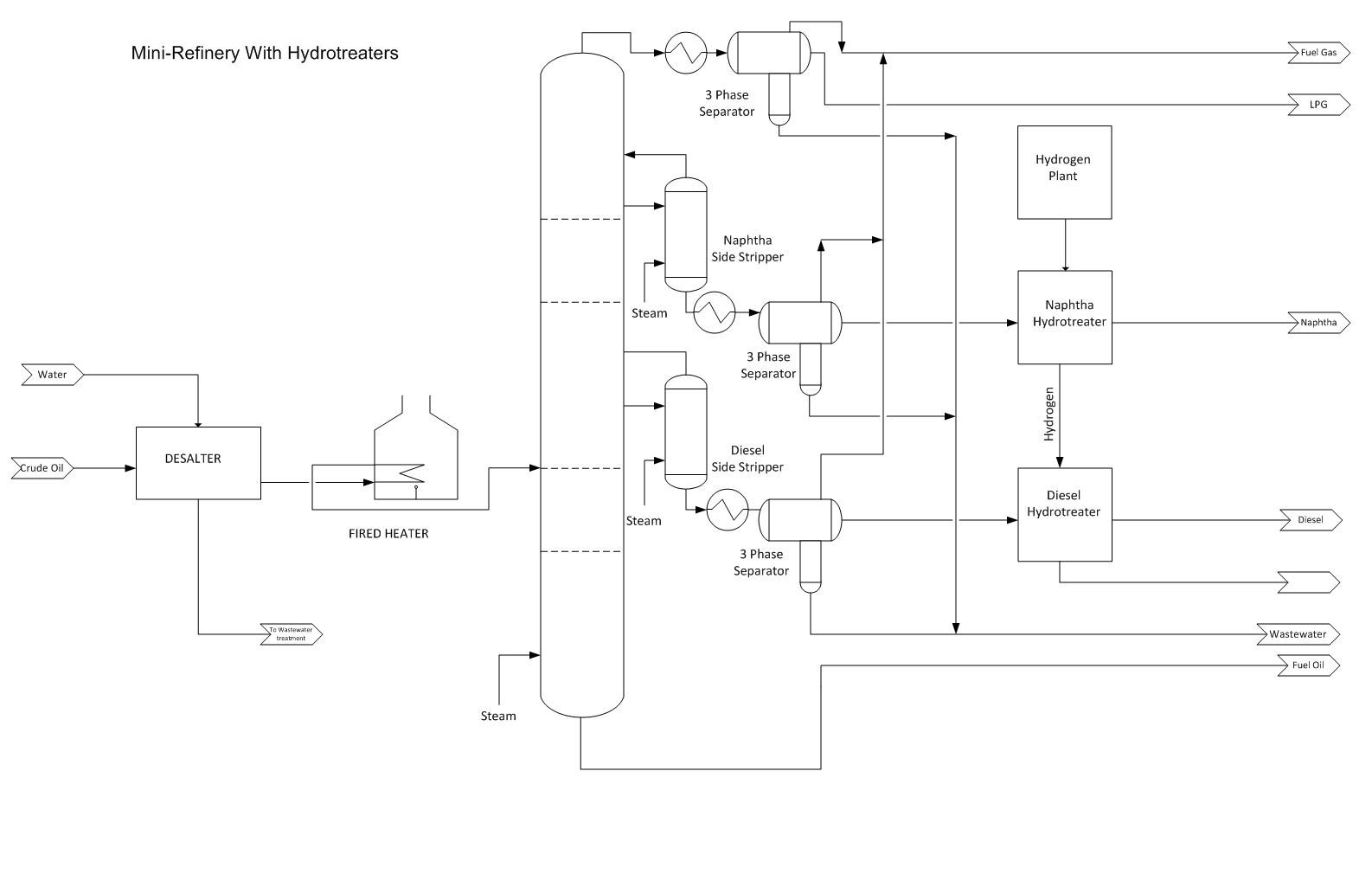

Let’s look at three variations of mini-refineries:

- A simple topping refinery

- A hydro skimming refinery with naphtha and diesel hydrotreaters

- A hydro skimming refinery with naphtha and diesel hydrotreaters and naphtha reformer

For the simple topping refinery, we have a gas-fired heater to heat the crude before the atmospheric distillation unit.

In the hydro skimming refinery with naphtha and diesel hydrotreaters (PFD 102), we have all of the above from PFD 101 plus a naphtha hydrotreater, diesel hydrotreater, and hydrogen plant.

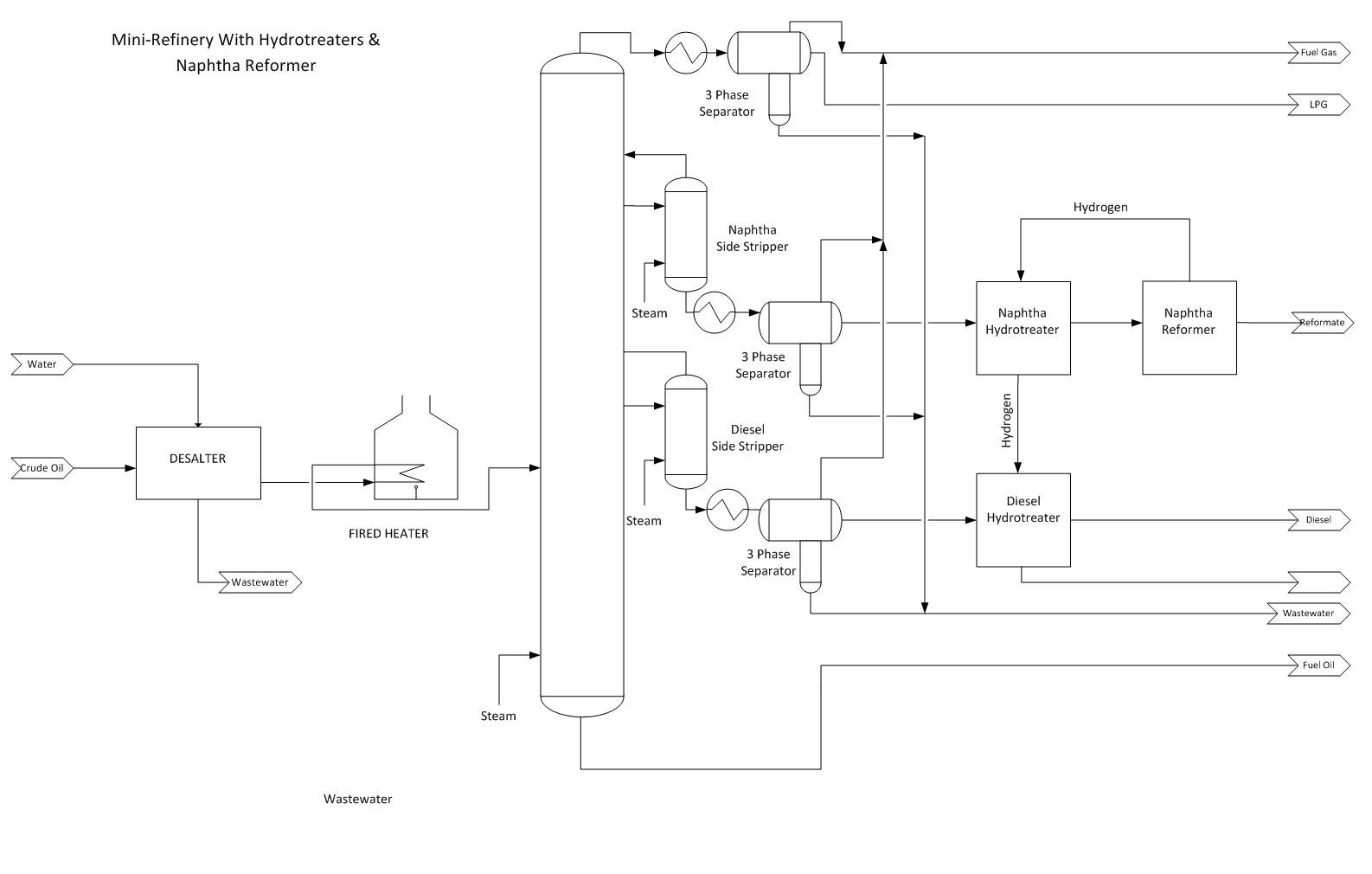

In the hydro skimming refinery with naphtha and diesel hydrotreaters and naphtha reformer (PFD 103), we have all of the above from PFD 102 minus the hydrogen plant plus a naphtha reformer.

Howebaker offers turnkey design solutions for mini refineries, with procurement & installation worldwide. They provide first-class Mini Refinery solutions with quality components and instrumentation & controls, safe designs, and high on-stream factors.

Howebaker designs mini-refinery plants using both new and refurbished process units, many using a skid-mounted modular structure, installed on concrete-slab foundations. When building a new plant, process equipment typically represents approximately 20% of the capital costs. Smaller unit operations are made possible by modular mini-plant designs, translating into a more compact plant with less structural steel, piping, conduit, and wire. The smaller size of the equipment may even allow savings on concrete foundations. Overall, modular or mini-plants mean less expensive plants with smaller footprints. In addition, many mini-plants are designed using refurbished process equipment, which can lower costs even further and accelerate the completion schedule.

Designing mini-refineries from the simplest straight run diesel production plants to more sophisticated hydro-treating refineries is increasingly becoming a flexible and cost-effective option for fuel producers in smaller, less-accessible areas. In this niche market, there is a need to adapt rapidly to satisfy local fuel needs. With new oil fields being discovered all the time, these plants can be easily moved from one location to the next or transformed into larger or redesigned plants. This gives the fuel industry low capital costs and a fast turnaround time, thus bringing them rapid returns on their cost/barrel investments.

Howebaker’s engineering firm designs modular mini-refineries sized from 2,000 to 20,000 barrels per day. Most other refinery plant engineering firms are too large to deal in these smaller capacities, with typical projects in the tens of thousands of barrels/day. Their plant designs are customizable. Their seasoned engineers can incorporate the best new and used process equipment to create the most advanced mini-refinery for your needs.

Their mini-refineries can produce a variety of products from naphtha, gasoline, jet fuel, and diesel. These process units are also designed for efficient processing of various crude products. In addition, vacuum tower bottoms can easily be converted to paving grade asphalt.

Let Howebaker work with you to design and build the refinery that meets your quality requirements on schedule and within budget.