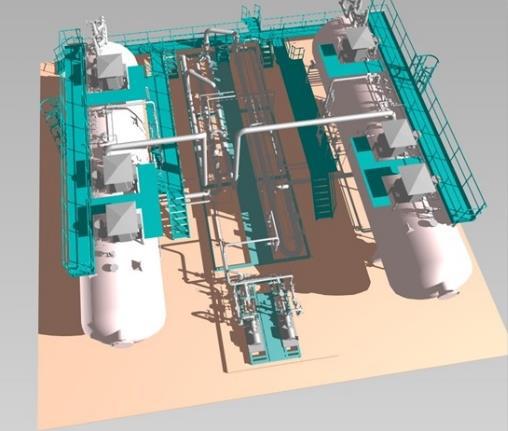

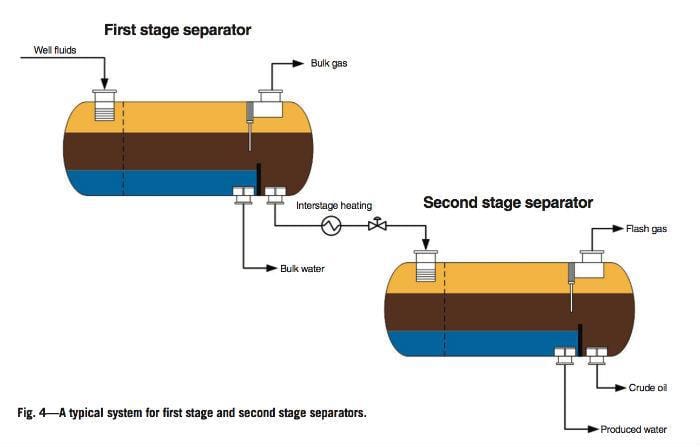

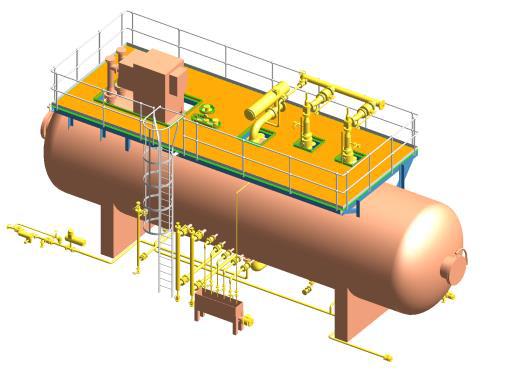

Howe Baker International Ltd has many years of experience in designing and supplying single or multi-stage separators for use in oil production schemes.

In order to optimise the initial separation stage and to minimise chemical usage, Howe Baker in conjunction with independent laboratory studies has refined the design of its separator internals, resulting in an extremely efficient and compact separator design suitable for both onshore and offshore applications.

Having a compact separator design is of particular importance in offshore applications where space is at a premium.

Howe Baker separators have been used successfully in many applications both onshore and offshore.

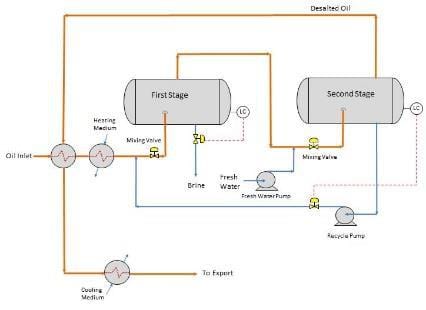

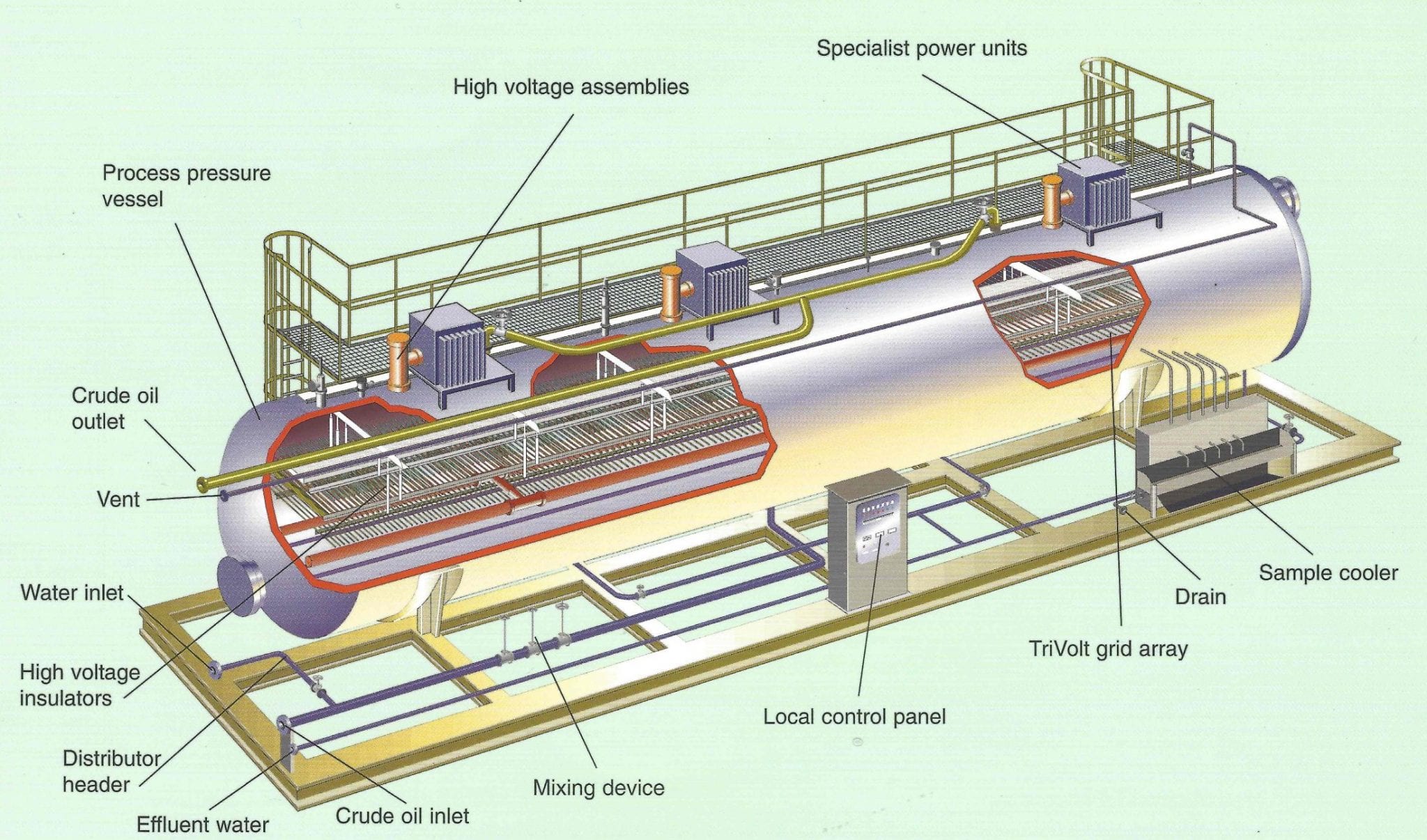

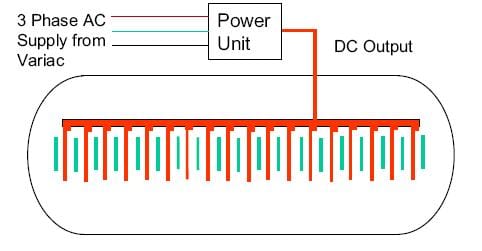

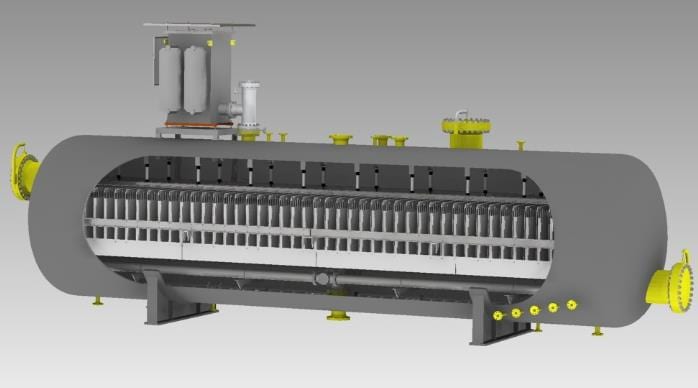

In order to remove the maximum amount of free water and therefore dissolved salts from a crude oil stream in the fastest possible time, the crude oil is fed into the dehydrators/desalters using Howe Baker’s specially designed distribution headers. These are positioned beneath a grid assembly mounted in a pressure vessel where the crude oil stream is subjected to a high voltage electrostatic field in which the water droplets are encouraged to coalesce and separate from the oil. Howe Baker’s desalter design, spaces and positions the electrical grids to ensure optimum power consumption and maximise the residence time of the crude oil between the grids, thus allowing more time for the water droplets to fall to the bottom of the vessel.

The water which contains the various impurities removed from the crude is continuously discharged into the effluent system for further treatment. Clean, dry crude oil flows from the top of the vessel for export or storage.

The efficiency of an electrostatic desalting system is linked to the intensity of the electrostatic field within the desalter vessel. Typically, a field of 20,000 volts is required. A special feature of all Howe Baker desalters is the PTB certified power units. These are a special purpose design and are 100% reactive and therefore cannot be overloaded.

This ensures that they remain on line under all conditions thus maintaining the unit’s efficiency.

In refinery operations where the export quality crude may contain up to 100 pounds of salt per thousand barrels of crude, a two-stage desalting operation may be needed to reduce the salt content down to as little as lppm to reduce downstream corrosion and catalyst poisoning. In a two-stage desalting system, wash water can be added to dilute the formation water salinity and the salt content of the dehydrated crude. Howe Baker’s single stage systems are capable of removing approximately 97% of the inlet salt, whilst two stage systems would be expected to better 99% removal.