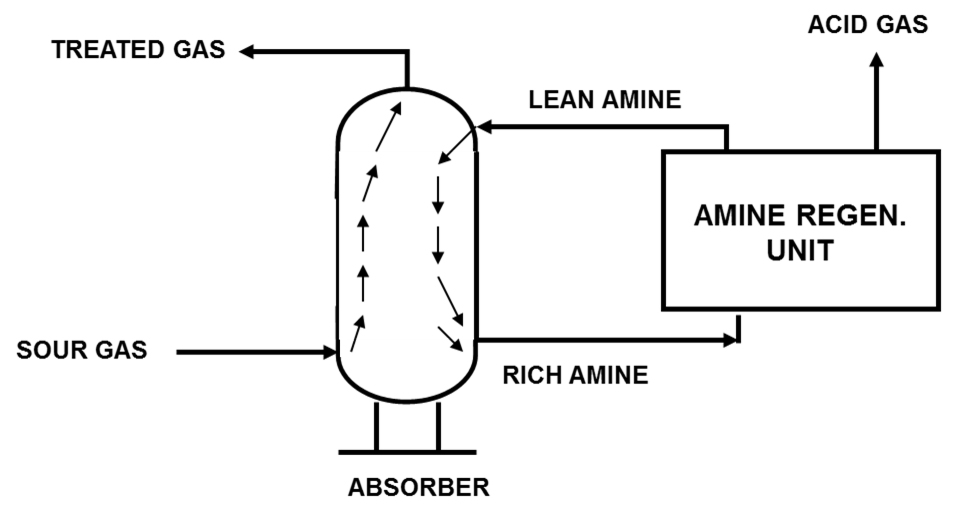

Hydrogen sulphide, carbon dioxide, mercaptans and other contaminants are often found in natural gas streams. H2S is a highly toxic gas that is corrosive to carbon steels. CO2is also corrosive in the presence of water to equipment and reduces the BTU value of gas.

Our field proven gas sweetening system remove these contaminants so the gas is suitable for transportation and further use.

Howe Baker designs and manufactures a variety of gas sweetening systems, including amine systems. Howe Baker offers a number of amine solvents that remove the contaminants by chemical reaction. Custom and standard designs are available to meet any gas sweetening challenge in the industry.